Aero-Plastics is a world-class provider of plastic product solutions, including machined nonmetallic and injection molded components utilizing high performance polymers and engineered resins.

Our CNC Plastic Machining Capabilities

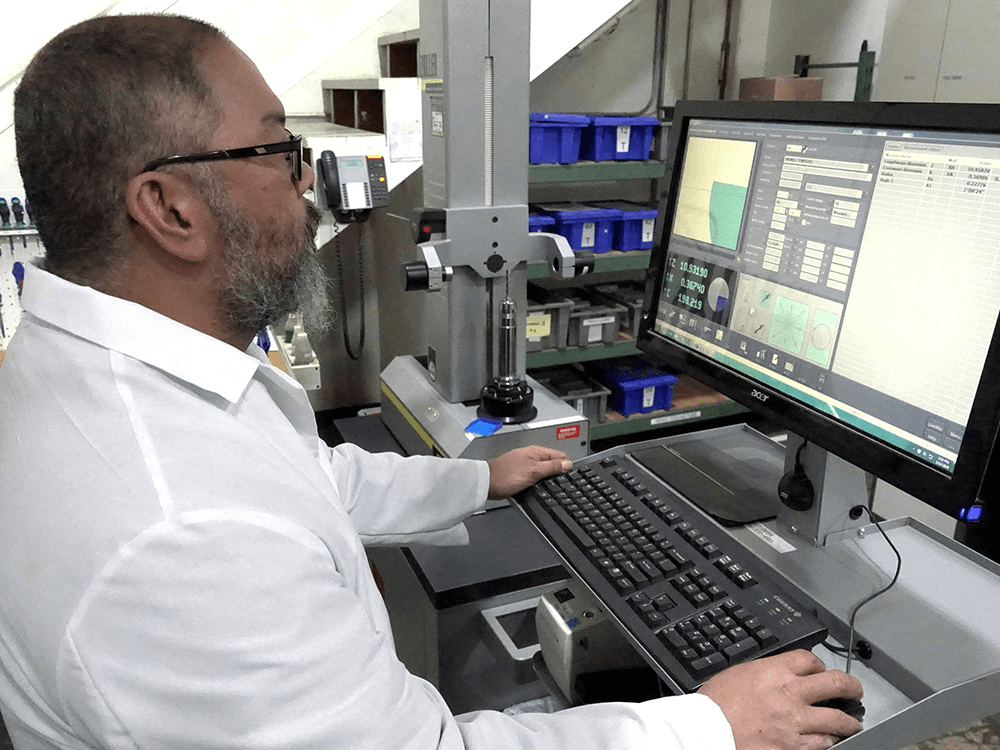

Aero-Plastics CNC plastic machining capabilities are best-in-class, offering an unparalleled experience. We can handle complex projects while maintaining a high level of accuracy.

Key processes include:

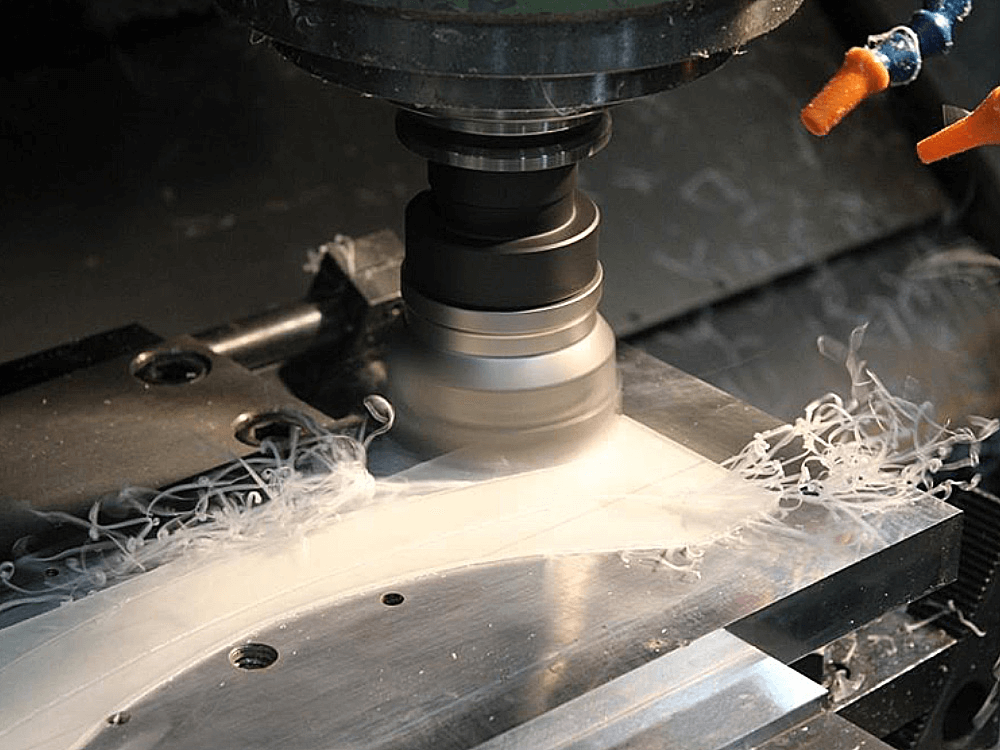

- 5-axis machining for complex geometries

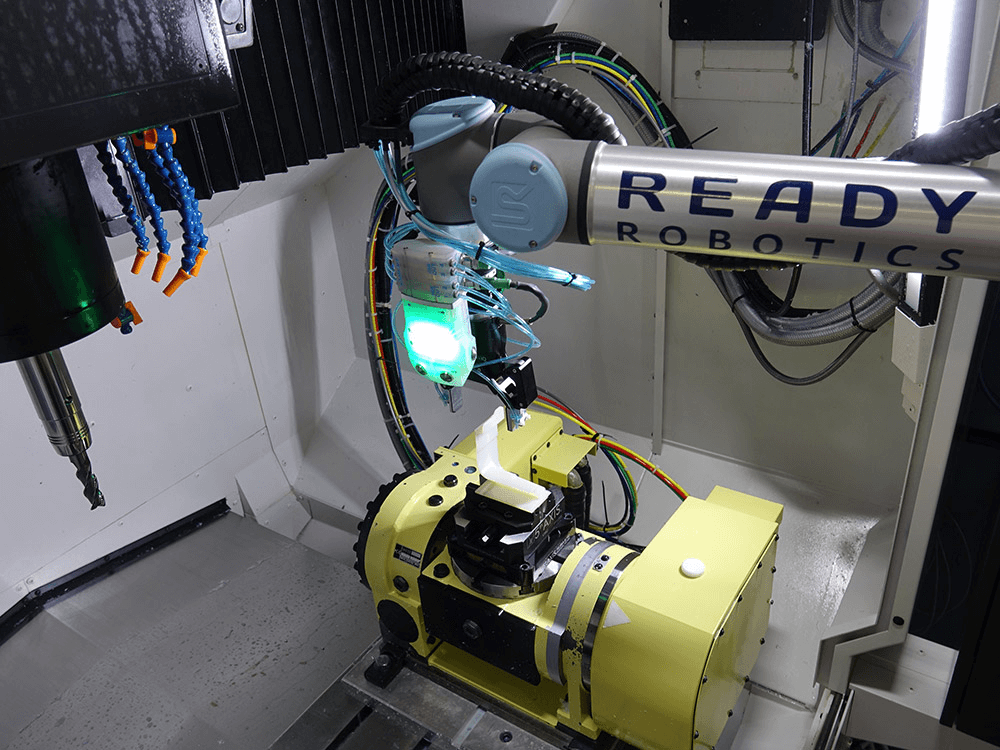

- State-of-the-art robotics provide maximum efficiency

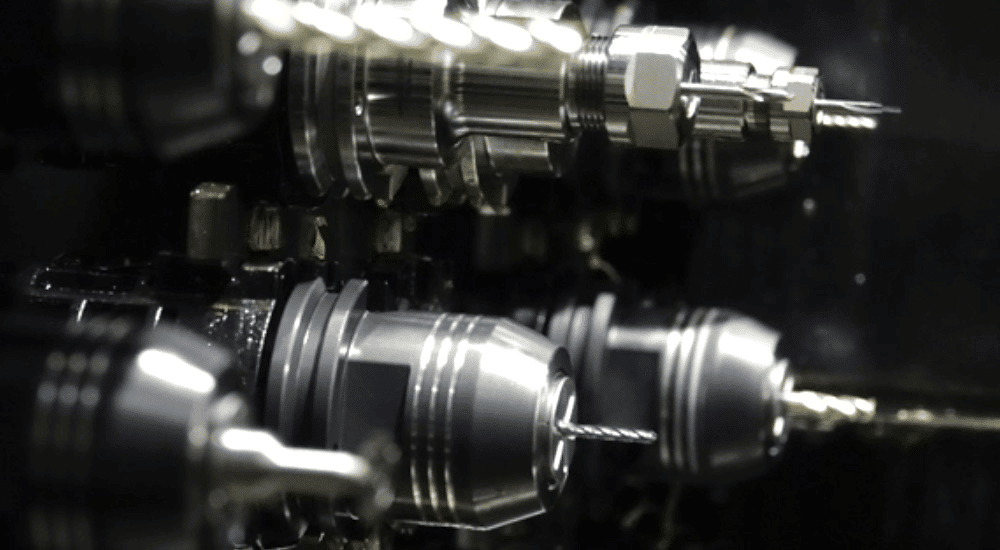

- Live tooling for fastest turnaround

- Ability to meet tight tolerances for demanding applications

Aero-Plastics has state-of-the-art CNC capabilities and expertise, including 5-Axis machining to handle your most complex machined plastic components.

Benefits of CNC Plastic Machining

There are many benefits to using CNC plastic machining, from cost to functionality.

Some of the benefits include:

Cost-effectiveness

CNC plastic machining can be used across different price points and budgets and delivers superior quality consistently.

Variety of materials available

With CNC plastic machining, you can work with a wide range of engineered materials to allow you greater flexibility in meeting your product requirements.

Annealing to reduce stress

The annealing process increases ductility and relieves any stresses absorbed by the machining process. Doing so improves the machinability of the metal.

Lightweight

Parts created through CNC machining are lightweight while still maintaining their strength.